Metal Stamping Company Serving Wichita, KS

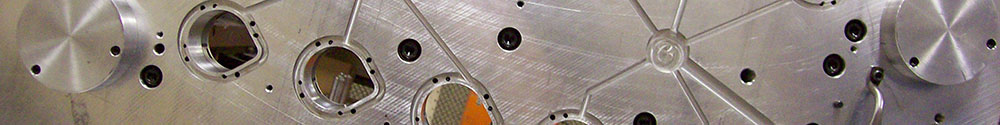

Natura Products, a precision metal stamping contract manufacturer with deep roots in cutting die manufacturing, is based in Northbrook, Illinois, USA and serves customers in Wichita, KS. Founded 61 years ago and trusted by some of the most recognizable companies in the world, we excel at short to medium run production of custom metal stamping components including: progressive die stamping, forming, countersinking, bending, compound blanking, piercing, flattening, coining and draw stamping.

- Expert in-house toolmaking

- Presses from 32 to 250 tons

- Quality manufacturing of stamped products

- Material thicknesses up to 0.250"

- Maximum bolster plate size of 58" x 24"

- Part tolerances down to 0.002"

ISO Certified

Natura Products is certified by UL DQS Inc. to the International Organization for Standardization ISO 9001:2015. We perform quality checks at various stages throughout the metal stamping process using sophisticated, certified, calibrated QC measuring instruments and equipment.

Trusted Worldwide Since 1963

We design, engineer, and manufacture simple and complex stamped components including parts with intricate features, heavy-gauge parts, miniature parts and parts made from high-strength materials that involve critical shape & surface features:

- Brackets

- Connectors

- Clamps

- Automotive Components

- Retainers

- Heavy Equipment Parts

- Food Processing

- Hoists

- Farm Implements

- Aircraft Components

- Valves

- Mounting Plates

- Clips

- Levers

- And More...

3 Affiliated Companies Under 1 Roof

With an array of nearly 200 tools — including stamping presses and CNC/manual machining tools — under one roof in our 80,000 sf facility, Natura Products is well-positioned to provide metal stamping services for customers in Wichita, Kansas. And, we can easily scale when a customer's technology, materials, volume, or requirements change. As one of three affiliated companies under one roof, we provide a single source for low volume precision machining, high volume precision machining, micromachining, wire EDM, and metal stamping.

Materials We Stamp

Our precision metal stamping presses handle a variety of materials such as:

- Carbon Steel

- High Strength Steel

- Plastic

- Ferrous and Non-Ferrous Metals

- Aluminum

- Brass

- Copper

- Galvanized Steel

- Nickel and Nickel Alloys

- Rubber

- Stainless Steel

- And More...

Design & Engineering

When it comes to cost reduction, new applications, or product improvements, metal stamping projects often require design & engineering expertise. Whether you have simple sketches on the back of a napkin or detailed drawings, our Certified SolidWorks Professionals will evaluate your concept and suggest improvements to maximize efficiency and productivity rooted in 61 years of experience.

- High performance

- Maximum efficiency

- Superior technical and troubleshooting know-how

- Custom solutions for any challenge

- Serving customers in Wichita, KS

Comprehensive Secondary Services

- Welding

- Machining

- Painting

- Reaming

- Spotfacing

- Coating

- Washing

- Deburring

- Polishing

- Powder Coating

- Assembly

- Plating

- Part Flattening

- Tapping

- Heat Treating

Natura Products is certified by UL DQS Inc. to the International Organization for Standardization ISO 9001:2015. We are an affiliate of Chicago Cutting Die and a global supplier of high-performance matched dies, stamping, and wire EDM. Natura was established in 1963 by a former Chicago Cutting Die employee, Dick Brettner. Dick named his new company after his first customer: the Field Museum of Natural History.

Dick was a talented die maker and a trusted outsource partner of Chicago Cutting Die for decades. When Dick retired in 1985, Chicago Cutting Die's holding company acquired Natura Products. In 1995, both companies moved to Northbrook, Illinois. The companies now share a facility and a commitment to precision, quality, and personal service.

- over 40 industries served

- customers in 22 countries

- nearly 200 machines & tools

- 80,000 square foot facility

- 3 affiliated companies under one roof

- 1 point of contact

-