Metal Stamping

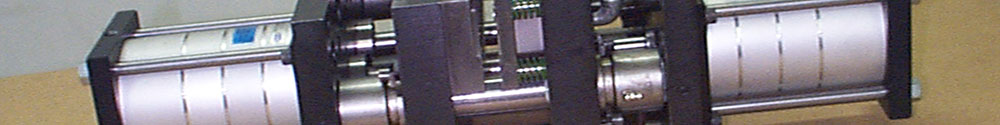

Metal stamping is the process of converting flat metal into specific shapes. Natura Products excels at short to medium run production of progressive die stamping, draw stamping, compound blanking, piercing, countersinking, coining, bending, forming, and flattening projects.

- Quality manufacturing of stamped products

- Presses from 32 to 250 tons

- Maximum bolster plate size of 58" x 24"

- Material thicknesses up to 0.250"

- Part tolerances down to 0.002"

We design, engineer, and manufacture simple and complex stamped components including parts with intricate features, parts made from high-strength materials, miniature parts, and heavy-gauge parts that involve critical shape & surface features. Valves, farm implements, hoists, heavy equipment parts, aircraft components, automotive components, food processing, brackets, clamps, clips, connectors, levers, retainers, and mounting plates are examples of some of the stamped products we produce.

Comprehensive Secondary Services, Too

Additional secondary services include assembly, washing, deburring, part flattening, machining, tapping, reaming, welding, spotfacing, plating, coating, heat treating, powder coating, painting, and polishing.

Materials We Stamp

Our precision metal stamping presses handle a variety of materials such as aluminum, brass, copper, carbon steel, high strength steel, galvanized steel, stainless steel, nickel and nickel alloys, ferrous and non-ferrous metals, plastic, rubber, and more.

With an array of nearly 200 specialized CNC and manual machining tools under one roof in our 80,000 sf facility, Natura Products is well-positioned to serve any contract metal stamping challenge. Natura Products is certified by UL DQS Inc. to the International Organization for Standardization ISO 9001:2015.